In the field of industrial equipment, after-sales service has long ceased to be merely a cost center and has become an important component of a company's core competitiveness. Traditional after-sales models are facing challenges such as slow response, high costs, and low efficiency. The application of 3D industrial simulation animation technology is reshaping the value chain of industrial after-sales services, promoting its transformation from passive repair to proactive service, and achieving a dual improvement in efficiency and customer satisfaction.

Visual Guidance: Reshaping Maintenance Service Processes

Industrial equipment is complex, and the maintenance process often relies on engineers' personal experience and professional skills. 3D simulation animation, through precise visual demonstration, transforms complex maintenance procedures into intuitive operational guides, significantly lowering the technical threshold.

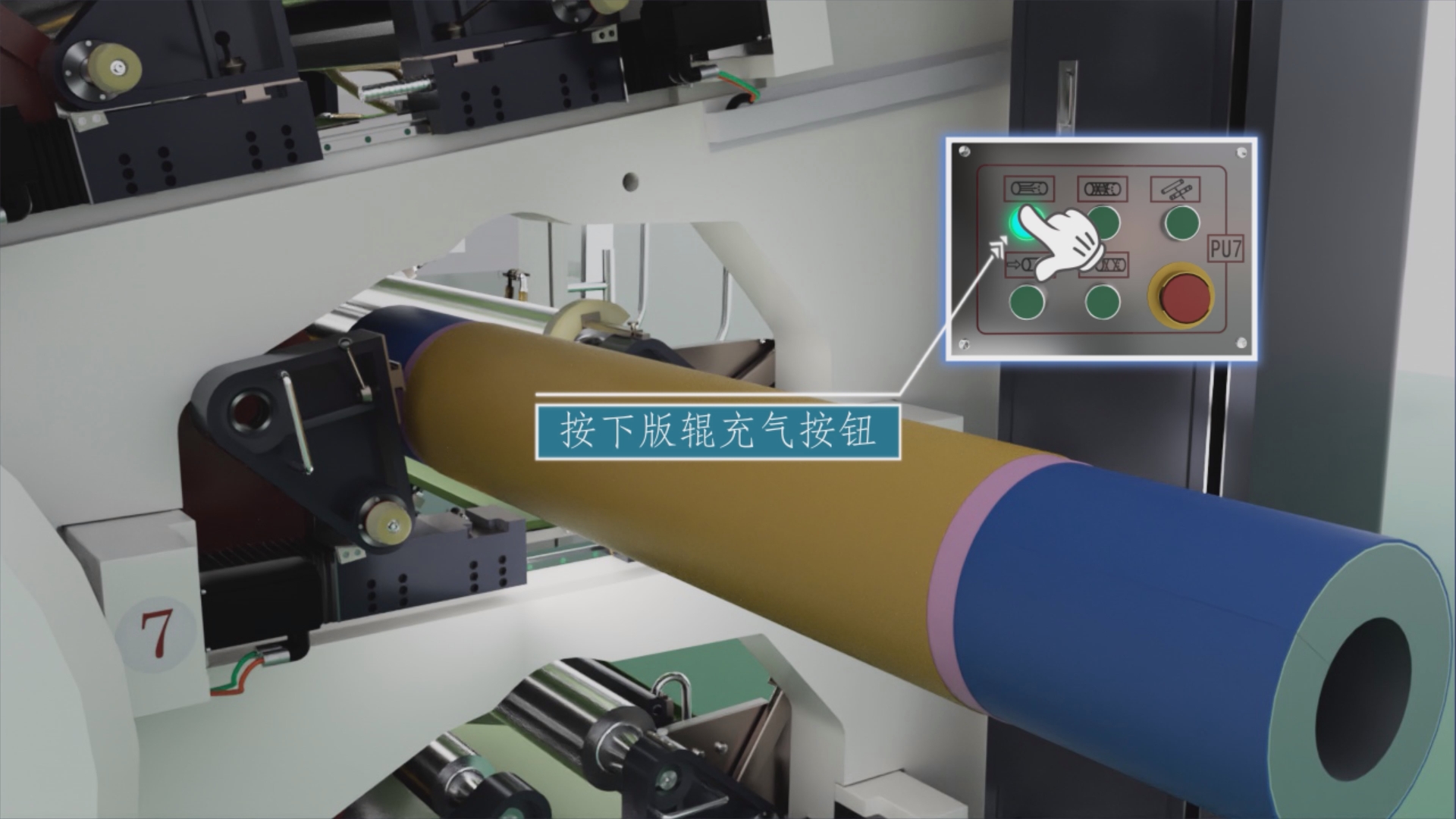

The ink printing press maintenance animation from Guangdong Topin Intelligent Machinery Technology Co., Ltd. details the complete process from fault diagnosis, component disassembly to replacement and assembly. Maintenance personnel familiarize themselves with the operation steps in advance through the animation, leading to an approximate 35% increase in on-site maintenance efficiency and a 50% reduction in error rates. This "simulate first, then operate" model not only shortens maintenance time but also prevents secondary damage caused by improper operation.

In the practice of Ruichang Carton Machinery Manufacturing Co., Ltd., 3D training animation supports maintenance personnel in repeatedly practicing fault handling procedures. By simulating various fault scenarios, maintenance personnel can calmly handle even rare faults, reducing the average maintenance time to 70% of the original, and significantly reducing customer downtime losses.

Remote Collaboration: Intelligent Support Breaking Space-Time Limits

When customer equipment malfunctions and experts cannot immediately reach the site, 3D simulation animation becomes a powerful assistant for remote guidance. Through animation demonstrations combined with video conferencing, technical support staff can clearly guide on-site operations.

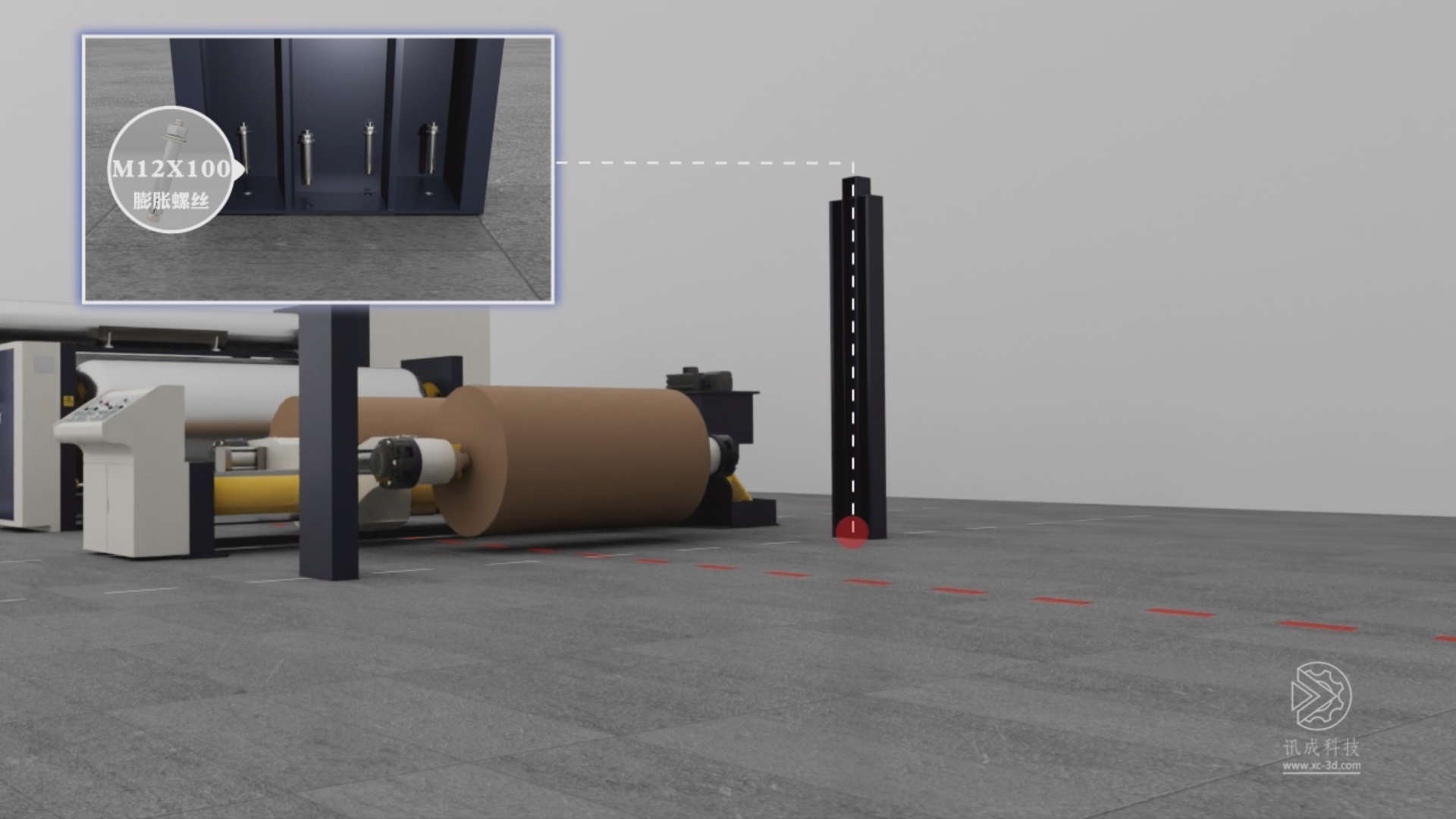

The installation animation project by Guangdong Zhaoqing Xijiang Machinery Manufacturing Co., Ltd. played a crucial role during the pandemic. By demonstrating the installation sequence and debugging parameters of equipment components, combined with real-time communication via video conferencing, it successfully resolved the predicament of engineers being unable to be on-site, ensuring the normal progress of projects.

The fault diagnosis animation from Shenzhen Wander Digital Technology Co., Ltd. elevates remote support to a new level. Technical support staff visually demonstrate troubleshooting steps to customers by retrieving corresponding fault animations, enabling customers to independently handle about 60% of common faults, greatly reducing service costs.

Preventive Maintenance: From Passive Response to Proactive Prevention

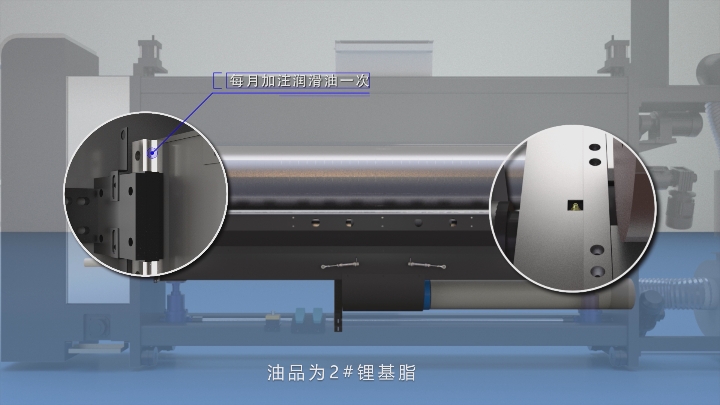

3D simulation animation shows great value in the field of preventive maintenance. By visually demonstrating equipment maintenance points, locations of wear parts, and replacement cycles, it helps enterprises establish scientific preventive maintenance systems.

The multilingual maintenance animation from Foshan Jinbing Machinery Co., Ltd. clearly marks equipment maintenance points and inspection standards. By regularly watching the animation, customers have developed good preventive maintenance habits, leading to a decrease of approximately 40% in sudden equipment failure rates. This proactive prevention model not only enhances equipment reliability but also strengthens customer loyalty.

Standardized Service: Enhancing Team Professional Capabilities

Inconsistent after-sales service quality is a challenge many companies face. 3D simulation animation, through standardized service processes, ensures that service personnel of different regions and skill levels can provide uniform, high-quality service.

The flexographic printing equipment interactive animation from Xiamen Sanlei Packaging Materials Co., Ltd. has become standard training material for the global service team. Through unified visual standards, newly hired after-sales service personnel can master core technologies in a shorter period, reducing the training cycle from three months to six weeks.

This standardization is not only reflected in internal training but also extends to customer guidance. The IGV intelligent forklift animation from Fujian FANGGUANG Shisheng Information Technology, with its multilingual versions, supports global customer operational training, ensuring consistency and accuracy in technical information transmission.

Value Transformation: After-Sales Service Becomes a Profit Center

The application of 3D simulation animation is changing the profit model of after-sales service. It shifts from traditional maintenance revenue to knowledge-based service output, opening up new growth spaces for enterprises.

The electromagnetic temperature control system maintenance animation from Dongguan Xusen Intelligent Technology, offered as a value-added service to customers, generates considerable service revenue. Customers are willing to pay for this knowledge product that reduces operational risks and improves production efficiency, transforming after-sales service from a cost center into a profit center.

More importantly, high-quality after-sales service has become key to differentiated competition. Statistics from Guangdong Hengli Intelligent Equipment Co., Ltd. show that customers who received systematic animation training have a 25% higher repurchase rate than ordinary customers, fully demonstrating the commercial value of excellent after-sales service.

Future Outlook: An Intelligent After-Sales New Ecosystem

With the development of technologies such as digital twins and augmented reality, the application of 3D simulation animation in industrial after-sales will deepen. In the future, by overlaying 3D animations onto real equipment via AR devices, maintenance personnel can "see what needs to be fixed," further lowering the technical threshold.

After-sales service in the era of intelligent manufacturing will be an intelligent system that uses 3D simulation animation as a visual medium, integrating IoT data and AI analysis. This system will not only respond to customer needs but also predict needs and provide proactive services, ultimately achieving mutual improvement in customer value and enterprise value.

Featured FAQs:

Q: What are the occasions for disseminating animation videos?

A: Animation videos can be played in various occasions:

1. Exhibitions: Playing animation videos at exhibitions with many buyers can quickly capture customers' attention and facilitate in-depth communication.

2. Client Visits: It's convenient for new sales representatives to quickly get started with business; even novice salespersons can engage in in-depth communication with clients through animation videos.

3. Playback on Various Platforms and Official Websites: Such as Douyin, WeChat Channels, Xiaohongshu, etc., to quickly expand influence.

4. New Plant Planning: Breaking away from traditional CAD planar demonstrations, animation videos offer a more intuitive way to showcase the rationality of new plant planning.

5. After-Sales Service: Demonstrating equipment operation, maintenance, and repair through animation videos is intuitive and easy to understand, not only significantly reducing after-sales service costs but also helping to increase customer stickiness.

6. Training and Educational Venues: Animation videos are important teaching tools, helping students and trainees to intuitively understand and master knowledge.

Q: How can small companies without an "Equipment Operation Manual" produce operation and maintenance animations?

A: Xuncheng can provide a full-chain service for equipment operation and maintenance animation production. Specifically:

1. After equipment installation and debugging, machinery factories can record on-site training using multiple fixed cameras and convert it into documents (Xuncheng can also provide this service);

2. Xuncheng classifies and optimizes the relevant content;

3. The document is sent to the machinery factory for confirmation;

4. Animation production.

Q: Which equipment is suitable for producing operation and maintenance animations?

A: Almost all equipment is suitable for producing operation and maintenance animations, from large single units worth millions to small equipment costing tens of thousands or even thousands of yuan.

Producing equipment operation and maintenance animations not only solves after-sales service issues but also creates a premium for the company's brand and products, better promotes sales, and enhances customer loyalty.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients range from startup teams and overseas clients to listed companies and foreign-funded enterprises. We specialize in providing 3D animation creation for mechanical equipment, high-tech, software development, foreign trade companies, etc. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at exhibition sites or during client visits; whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented in astonishing 3D animations. This not only brings unique visual experiences to customers but also quickly impresses them.